Description

◆Feature

•TM type has been developed exclusively for the injection molding machines. Since it is of fixed type,

the die standard is required.

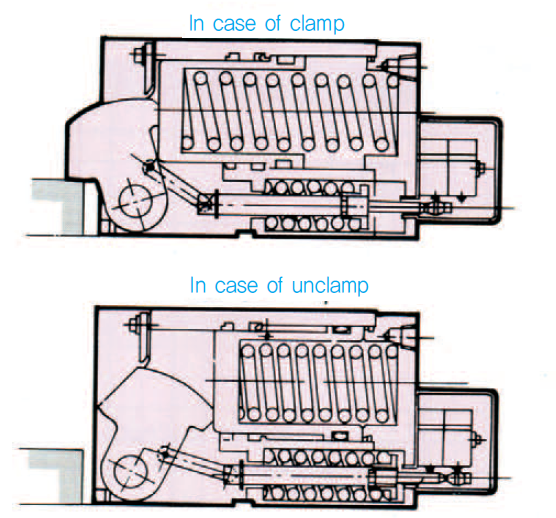

•Since the lever does not project after unclasping, there is no interference while exchanging dies.

•This type can be userd without the T-slot.

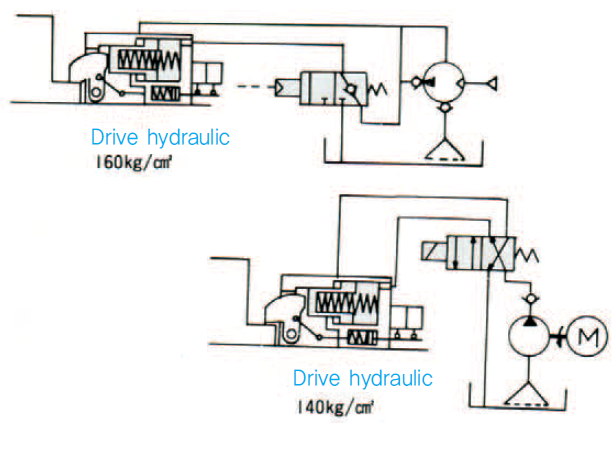

◆Circuit diagram

◆Structure

| ① Nominal Clamping Force | |

| 2 | 2 ton |

| 4 | 4 ton |

| 6 | 6 ton |

| 10 | 10 ton |

| ② Die Height(mm) : L(mm) |

◆Common items

| Specifications

Type |

TM1 | TM2.5 | TM4 | TM6 | TM10 | |

| Normal clamping force(ton) | 1 | 2.5 | 4 | 6.3 | 10 | |

| Spring supporting force(ton) | 0.05 | 0.1 | 0.16 | 0.25 | 0.4 | |

| Full stroke(mm) | 3.5 | 4 | 4 | 4 | 4.5 | |

| Clamp stroke(mm) | 2 | 2 | 2 | 2 | 2 | |

| Safety stroke(mm) | 1.5 | 2 | 2 | 2 | 2.5 | |

| Unclamp Hydraulic(kg/ ㎠ ) | 30 | 30 | 30 | 30 | 30 | |

| Quantity of oil | CLAMP(cc) Clamp | 15 | 41 | 92 | 163 | 298 |

| UN-CLAMP(cc) Unclamp | 6 | 11 | 28 | 48 | 87 | |

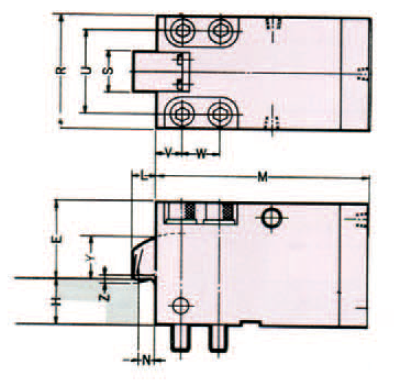

◆Shape & Measure

| Specifications

Type |

E | L | M | N | R | S | U | V | W | Y | Z | X | H |

| TM1 | 42 | 11 | 118 | 9 | 52 | 18 | 38 | 12 | 18 | 2 | 1.5 | M8 | MIN.20 |

| TM2.5 | 56 | 16 | 145 | 12 | 78 | 27 | 58 | 17 | 22 | 2 | 2 | M10 | MIN.30 |

| TM4 | 76 | 19 | 177 | 14.5 | 88 | 35 | 68 | 20 | 26 | 2 | 2 | M12 | MIN.30 |

| TM6 | 90 | 21 | 197 | 15 | 108 | 45 | 84 | 22 | 30 | 2 | 2 | M14 | MIN.35 |

| TM10 | 112 | 25 | 236 | 19 | 135 | 55 | 106 | 30 | 36 | 2 | 2.5 | M18 | MIN.40 |

| See also different: | |